Konica Minolta South Africa continues growing its reputation within industrial print markets after several successful digital label press installations.

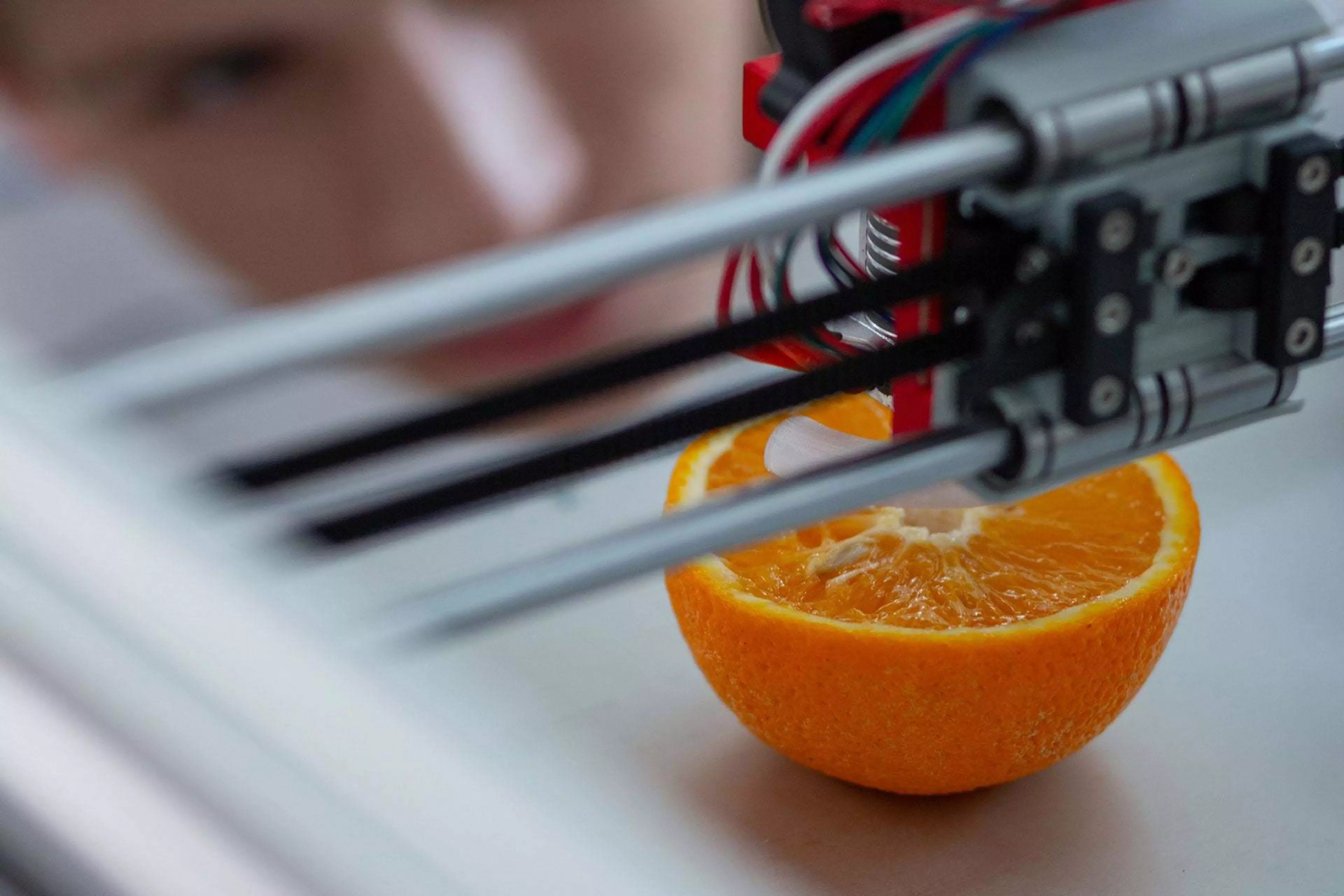

Konica Minolta South Africa (KMSA) launched the AccurioLabel 190 digital label press to the South African market which has been developed and manufactured in cooperation with Danish company Grafisk Maskinfabrik (GM).

Konica Minolta’s AccurioLabel 190 provide a range of new benefits such as in-line finishing capability, slitting while printing, accommodates larger media rolls to promote uninterrupted printing for 1 000 linear meter, single-phase power, web guiding systems on both unwinder and rewinder as well as pneumatic tension control to mention but a few.

The AccurioLabel 190 fills the gap between entry level and high-end digital printing presses and will benefit clients from stable colour consistency while using true 1200 x 1200 dpi at 8 bit colour technology to produce offset-like quality. No pre-coating is required avoiding additional label manufacturing costs, providing a wider selection of media capabilities from traditional media suppliers as well as an increase in productivity. Converters benefit from its ease of operation, production flexibility, fast turnaround and variable data printing capabilities, as well as world-class local support, service, spares and consumables throughout KMSA’s 70 direct and indirect channels in Southern Africa.

The AccurioLabel 190 allows label converters to capitalise on the short-run market – a sector that has traditionally been difficult and expensive to enter with current label technologies. Although the AccurioLabel 190 press has all the quality characteristics of high-end machines, it offers the convenience of smaller systems, and is perfect for the versioning of variable data labels, label proofs, sampling, short runs on-the-fly and custom designs for promotional purposes. It is a truly complementary system that can benefit existing label converters as well as giving new printers an opportunity to enter the market. In addition, KMSA is offering users an all-inclusive maintenance charge. This static, unwavering ‘flat rate’ cost is hugely beneficial to label printers as it allows them to prepare an accurate estimate for any job, eliminating the risk of potential loss through incorrect cost calculations.

Konica Minolta’s proven digital electrophotographic dry toner technology for labels is used extensively at customer sites across the world and this includes several successful installations in Southern Africa.

See what clients have to say about the Konica Minolta digital label press:

“The Konica Minolta machine gives us exactly the quality we are looking for. The print results are good, resembling offset, and the colours remain in place – scratch-resistant. Moreover, the physical dimensions of the machine were absolutely ideal for us.” Jarle A. Skarseth, General Manager.

“We were aware of the good quality and reliability that Konica Minolta stands for in general. When we looked at the machine and analysed the combination of the print quality and the price, we were fully convinced: the print quality can definitely keep up with machines in the higher segment. And a couple of our customers without experience in digital were really blown away. Additionally, we value the personal relationship with the Konica Minolta representatives, it ‘felt right’ from the start. This acquisition surely paid off well for us.” Phil Achurch, General Manager.

“The fact that we can now meet requirements for short runs and fast turnaround times will surely pay dividends. The quality produced off the Konica Minolta digital label press is undeniably superb. Another plus point is that no pre-treatment of materials is required. Not only is this press amazingly compact, it is also easy to run.” Henk Crous, Owner.

For detailed information please see: https://labelprinting.konicaminolta.eu