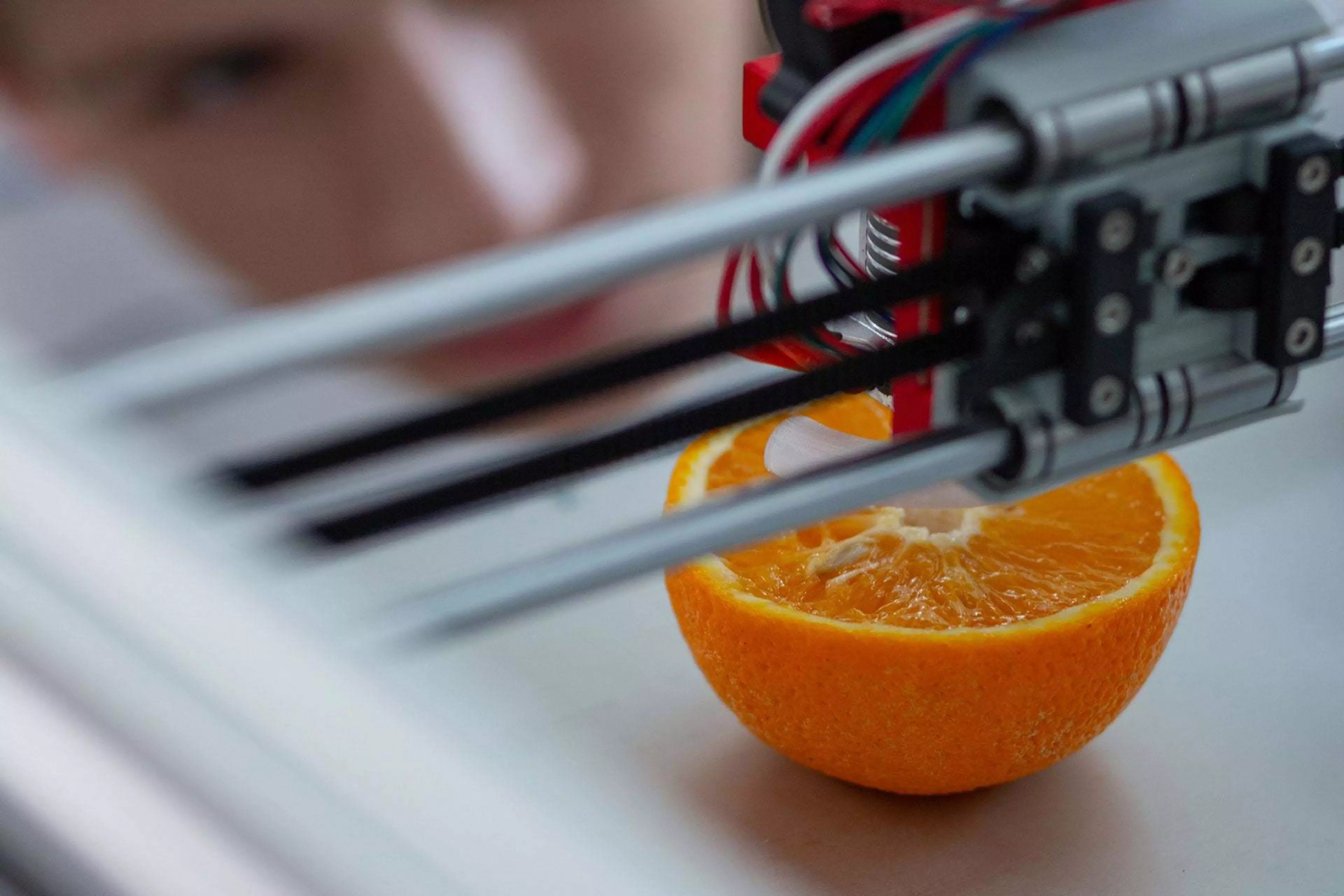

Introducing the AccurioPress series, designed to add productivity, performance and simplicity to any production print environment. Real-time image and colour density control sensors, automatic front and back registration, hands-free in-line colour profiling and automatic colour adjustments.

With advance key features that includes improved media flexibility, an increase in productivity, enhanced quality precision and consistency as well as a full range of professional in-line finisher options.

Konica Minolta’s Versatile New Series for the Commercial Printing Industry

Konica Minolta’s new Accurio series sets new standards for superior performance and unsurpassed value, combining digital colour quality that rivals offset prints with advanced workflow and colour management tools that fine-tune accuracy and are designed to keep costs down. It’s a comprehensive and fully modular line of digital printing technologies and solutions, including digital press suites, software and cloud-based tools for integrating, managing and executing seamless workflow.

Derived from the word ‘accurate’, Accurio reflects the advanced, automated and accurate nature of the company’s technology.

Some of the key features include:

- Delivers amazing colour that rivals offset and meets colour standards such as G7, Gracol and FOGRA

- Quickly produces banner prints suitable for book jackets, tri-fold brochure and menus, panoramic posters and more

- Produces completely finished, professional saddle-stitched books ready for distribution

Some of the new range of bold media options include:

- Printing on heavy stocks up to 350gsm and\or 400gsm including auto duplex on this grammage

- Productive high volume 750mm banner printing with the new LU-202XL paper tray

- Extended banner ability of up to 1200mm through the external banner tray

- Auto duplex banner size of 762mm

- More productive envelope printing with a variety of configurations

- Specialised media support, textured paper, support for cut sheet label media

- A wide variety of advanced finishing equipment

“This new, comprehensive and fully modular line of digital printing technologies and solutions maximises the use of resources, reduces labour costs and also increases accuracy and productivity,” said Leon Minnie, production print manager at Konica Minolta South Africa, “This versatile series meets the print industry requirements for increased output and versatility.”

Konica Minolta’s AccurioPress series Achieves FOGRA Certification

Konica Minolta’s AccurioPress C2070 series was awarded FograCert Validation Printing System (VPS) certificate.

This high-speed colour digital system takes image quality and consistency to new heights, and underwent a series of tests to secure the accolade from the German-headquartered FOGRA Research Institute for Media Technologies.

“The FOGRA certification mirrors the feedback we get from customers on the fantastic features and productivity found in the AccurioPress C2070 series. It also highlights that the latest addition in our portfolio meets the highest industry standards offering our customers further quality assurance through world-class productivity, reliability and print quality, for which Konica Minolta is renowned,“ concludes Leon Minnie, manager of production print at Konica Minolta South Africa.

FOGRA found that the Konica Minolta AccurioPress C2070 series ‘fulfils all criteria of this programme in the tested configurations’. It is now certified when running with the optional EFI Fiery, CREO or Konica Minolta controllers.

The Konica Minolta AccurioPress C2070 was tested in a number of configurations and printing conditions for a wide range of capabilities. These included PDF/X conformance, proofing substrate colour, gloss and fluorescence, colour accuracy, uniformity, permanence and light fastness. Tests also considered fading, long and short-term repeatability, rub resistance of the print, colourmetric tone value transfer, tone value reproduction limits, image register and resolving power and margin information.

The Konica Minolta AccurioPrint C2070 delivers outstanding colour and registration stability combined with excellent print quality. Its improved thick paper support allows the use of various media types, such as coated and embossed paper up to 350gsm. In addition, a new, large capacity unit for banners up to 750 mm in size ensures efficient banner printing, such as for book covers and three-fold menus.

About FOGRA

The objective of the FOGRA Research Institute for Media Technologie is to promote print engineering and its future-oriented technologies in the fields of research and development, and to enable the printing industry to utilise the results of this activity. The association maintains its own institute, with about 50 staff members including engineers, chemists and physicists.

‘Simply efficient’ - AccurioPress C6100 Series

The AccurioPress C6100 Series is available in 85ppm, C6085 and the 100 ppm, C6100. The fast and flexible series has been created for operations that wants to expand their digital printing and are now expanding their service as well as those who need to handle large, repeat, print volumes. This new generation of true production systems has been designed to ensure improved uptime and deliver even higher quality printed materials with greater reliability and stability. With the Integrated Colour Care Unit they overcome some of the biggest pain points in digital print production such as time-consuming front to back registration, extensive colour set-up and complex paper set-up operations which are now something of the past. The AccurioPress C6100 Series will underpin Konica Minolta’s market-leading reputation for productivity, reliability and quality. They will meet and exceed the advanced requirements of print production environments at the highest levels, as well as offering digital image quality on par with offset printing. Uptime is assured via highly automated features such as automates colour adjustment, skill-less operation, constant control of gradation and front-to-back registration. Enhanced functions, including stabilised paper feeding, support a wide range of paper weights from 52gsm to 400gsm, plus embossed paper, encouraging broader production possibilities. Other enhancements include low-cost envelope printing, via a dedicated fusing unit – all of these features targeted at growing a printers business. Reliability and stability is further enabled by Simitri HD E toner for higher offset-like natural textures while lower temperature fusing reduces damage to paper resulting in higher quality finishes and improved environmental performance. The new series also delivers a top-class monthly duty. Collectively all these innovations have been combined into Konica Minolta’s fastest and most efficient automated press yet. The AccurioPress C6100 Series has been launched to help operations enhance their bottom-line with a production press that offers maximum uptime and job flexibility for maximum profit.